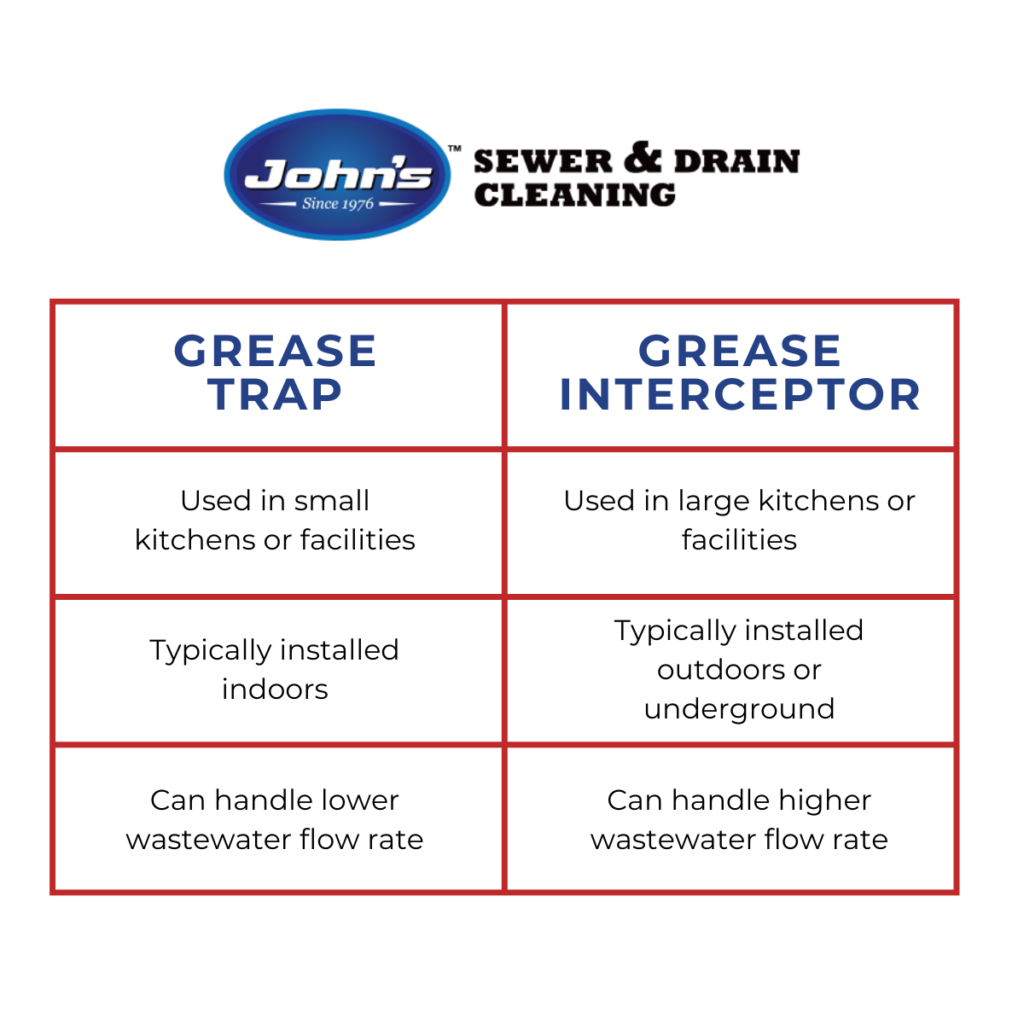

When it comes to managing grease waste in kitchen drain systems, two primary solutions are commonly used: grease interceptors and grease traps. Both serve the critical function of preventing fats, oils, and grease (FOG) from entering municipal wastewater systems, but they differ in size, design, functionality, and installation requirements.

Understanding the key differences between a grease interceptor and a grease trap is essential for commercial kitchens, restaurants, food processing facilities, and even residential kitchens that generate grease waste.

What is a Grease Interceptor?

A grease interceptor is a large, high-capacity unit designed to capture grease, oils, and solids before they enter the sewer system. These units are typically installed underground, outside a building, and are used in high-volume commercial kitchens that produce a significant amount of grease waste.

Key Features of Grease Interceptors:

- Larger capacity: Holds 500 to 5,000 gallons of wastewater, making it suitable for commercial kitchens.

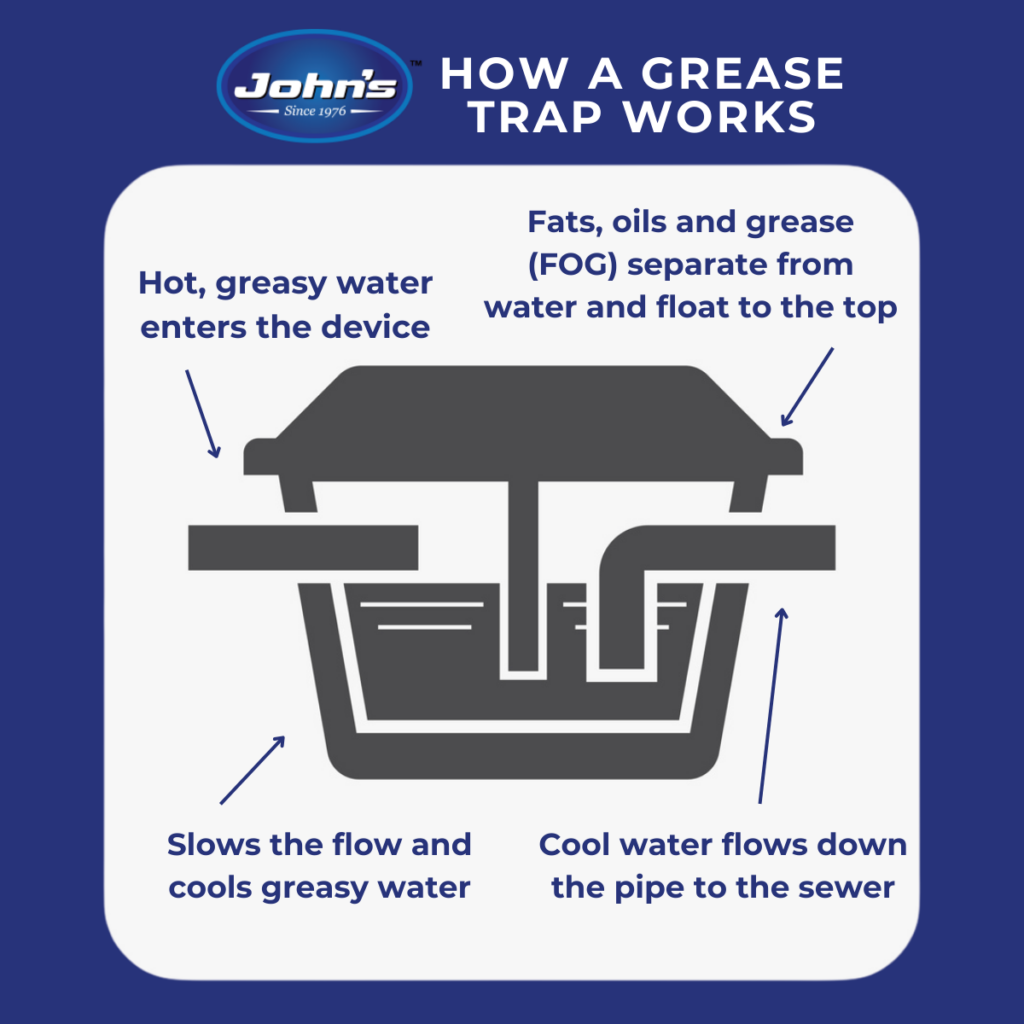

- Slower separation process: Wastewater is retained for an extended period, allowing grease and solids to separate naturally.

- Installed underground or outside the building: Typically located outside restaurants, cafeterias, and food service facilities.

- Less frequent cleaning required: Due to its larger capacity, cleaning is often required every three to six months instead of weekly.

Best Applications for Grease Interceptors:

- Large commercial kitchens (e.g., hotels, hospitals, schools, and universities).

- High-volume restaurants that produce large amounts of grease.

- Industrial food processing facilities.

- Institutional cafeterias.

What is a Grease Trap?

A grease trap, also known as a hydromechanical grease interceptor (HGI), is a smaller unit designed to trap grease and solids before they enter the plumbing system. Unlike grease interceptors, grease traps are usually installed indoors under sinks or near dishwashers.

Key Features of Grease Traps:

- Smaller capacity: Typically holds 10 to 50 gallons of wastewater, making it suitable for small-scale grease control.

- Faster separation process: Wastewater passes through a baffle system, which quickly separates grease from water.

- Located inside the kitchen: Installed under sinks or near dishwashing stations.

- Frequent maintenance required: Due to their small size, grease traps need to be cleaned often to prevent blockages.

Best Locations for Grease Traps:

- Small restaurants, cafés, and food trucks.

- Residential kitchens that require grease management.

- Establishments with limited kitchen space but still generate grease waste.

- Commercial dishwashing areas where a smaller unit is sufficient.

Grease Interceptor & Grease Trap Maintenance

Proper maintenance is essential to ensure that grease traps and interceptors function efficiently. Neglecting routine cleaning can lead to foul odors, slow drainage, and even costly fines for non-compliance with local grease management regulations.

Maintenance Tips for Grease Interceptors:

- Schedule routine cleanings every 1–3 months to remove accumulated grease and solids.

- Monitor grease levels and clean before reaching 25% capacity to avoid overflows.

- Inspect baffles and pipes for clogs and corrosion.

- Use enzyme-based treatments to break down grease and reduce buildup.

Maintenance Tips for Grease Traps:

- Clean at least monthly to prevent grease overflow.

- Use hot water and degreasing agents to break down accumulated fats.

- Check for food debris that may be clogging the trap.

- Keep a maintenance log to ensure compliance with local regulations.

Regular maintenance reduces plumbing issues and extends the lifespan of grease management systems. Hiring professional grease trap cleaning services can also ensure the thorough removal of grease and debris.

Impact of Local Grease Trap Laws

Many cities and states, including Massachusetts, have specific regulations regarding grease trap and interceptor system installation and maintenance. Failure to comply with these local regulations can result in fines, business closures, and environmental hazards.

Massachusetts Commercial Kitchen Grease Trap Guidelines

Massachusetts food service establishments must follow the state’s Department of Environmental Protection (MassDEP)’s grease management laws, which include:

- Mandatory grease trap installation for any facility discharging grease into the sewer system.

- Regular inspections and maintenance logs must be kept for health and safety compliance.

- Proper disposal of waste grease—grease cannot be dumped into drains or stormwater systems.

- Penalties for non-compliance, including fines and revocation of business permits.

In the city of Boston, grease traps should be cleaned when 25% of the liquid level of the trap is grease or oil, once a month minimum for point-of-use traps, and quarterly for large in-ground grease interceptors. Most grease traps should be completely emptied at least once a month.

How Can a Grease Trap or Interceptor Improve Your Business?

For restaurant owners, food service operators, and residential users, proper grease management is essential for a smooth-running kitchen and a healthier plumbing system. Investing in a grease interceptor or grease trap provides multiple benefits beyond regulatory compliance.

Key Benefits for Businesses:

- Prevents Plumbing Issues: Avoids costly pipe blockages and repairs due to grease buildup.

- Improves Kitchen Efficiency: Ensures smooth drainage and prevents foul odors that could impact food safety.

- Enhances Environmental Responsibility: Reduces pollution by keeping grease out of municipal wastewater systems.

- Ensures Health Code Compliance: Avoids fines and closures by adhering to local ordinances and grease management laws.

- Reduces Operational Costs: Lower maintenance costs by preventing major plumbing issues and sewer backups.

Understanding the differences between grease interceptors and grease traps is essential for businesses and homeowners looking to manage grease waste effectively. Grease interceptors are large, outdoor units designed for high-volume food service facilities. Grease traps are smaller, indoor units that require more frequent maintenance but are ideal for small businesses and residential use. Both systems help prevent grease-related plumbing issues, protect the environment, and ensure regulatory compliance.

Installing the right grease management system can save money, reduce maintenance headaches, and improve operational efficiency. At John’s Sewer, we specialize in sewer cleaning and grease trap services to help the greater Boston area maintain clear and functional drains. Give us a call today to learn more about our expert grease trap solutions.

FAQs

If you notice slow drainage, sudden bad smells, or grease buildup in your sinks and floors, your grease trap might need to be cleaned. However, sticking to a regular maintenance schedule will often help you avoid these issues altogether.

With proper upkeep and regular cleaning, a grease trap can last up to ten years. However, the exact timeframe will depend on the size of the device and how often it is used.

An overflowed grease trap usually occurs because of a blockage in the outlet line. It can cause contamination and lead to health code violations, so it’s important to contact a professional to get the issue resolved quickly. If you are in the Boston metro area, John’s Sewer provides 24/7 services and will be at your property within 2 hours of your call.